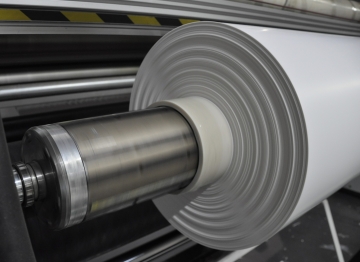

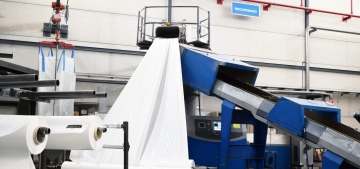

EXTRUSION

Our extrusion plant has a production capacity of 35,000 tons per year. We have high technology co-extrusion machines equipped with the best quality systems: gravimetric dosing, width control, thickness control, automated transport of formulas, etc. resulting in films with remarkable properties and up to 3.5 meters wide.

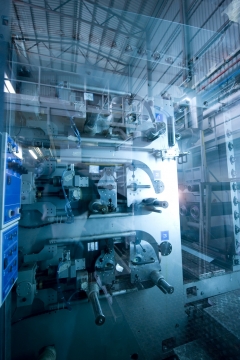

PRINTING

In the printing plant, we have the most modern printing machines on the market, all equipped with an adjustable Graphic Positioning System (GPS):

- 10-color printers.

- Maximum print width 1700 mm.

- Print speed: 1000 meters / minute.

- 100% real-time inspection and control.

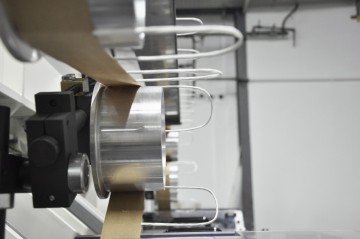

MANUFACTURE

The production plant has 50 high-performance machines to produce our wide range of bags: loop, patch, punch out, vest bag, block, e-commerce, envelopes, tamper-evident and security bags, paper bags, suit carrier bags, refuse sacks, etc. Thanks to our complete automation, we obtain finishes of superior quality, as well as great flexibility and agility in our service and delivery.

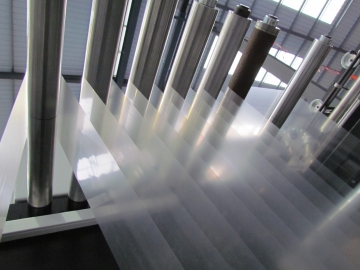

RECYCLING

The surplus production: Filos, dies, etc. As well as our shrinkages are classified by types of material and color. These are 100% recovered and conveniently stored in silos for later reintroduction into the production process giving rise to new plastic containers.